Market pressure, rising customer expectations and the EU’s CSRD reporting requirements are driving the shift towards a circular economy. Remanufacturing answers these demands for change and increases business value in a sustainable way. IFS Cloud helps manufacturing companies succeed in a changing market, as its built-in remanufacturing capabilities streamline the entire production value chain.

What are the benefits of remanufacturing?

Remanufacturing extends product lifecycles and puts value back into the loop. Companies take back used products, disassemble them, replace worn parts and deliver the product in like-new condition. This approach saves materials, reduces emissions and strengthens delivery reliability when critical parts are returned to use in a controlled way.

Remanufacturing benefits companies financially, as energy consumption is reduced by 60–85% compared to producing a new item, while the end customers receive the same performance as from a new product – and the planet wins too. Growing demand for sustainable products turns remanufacturing into a competitive advantage and creates new revenue streams for companies.

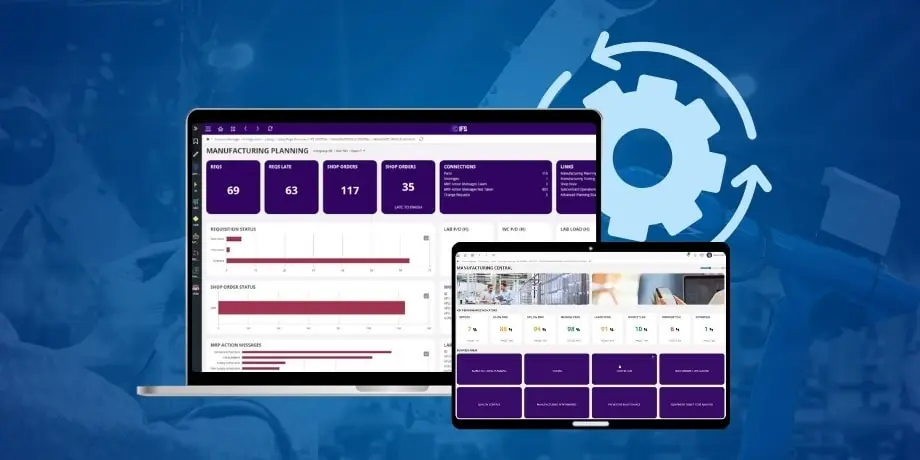

IFS Cloud Remanufacturing capabilities

In its 2024 report on remanufacturing software, IDC named IFS a leading product, which makes IFS Cloud a reliable long-term solution for managing remanufacturing.

IFS Cloud creates an operating environment where remanufacturing is carried out in a controlled way and scales with the business. Built-in remanufacturing capabilities standardize workflows from disassembly of parts to final product testing.

Here are four ways IFS Cloud supports remanufacturing:

1. End-to-end visibility across the supply chain

IFS Cloud tracks the condition, availability and cost of returned parts together with purchasing, inventory and deliveries in one place. This makes it clear how availability and return flows affect plans. Better forecasting reduces overstocking and frees up capital.

2. Unified control of new and returned materials

IFS Cloud manages the combined use of new and returned materials throughout the chain, from production planning and cost accounting to execution on the shop floor. Remanufacturing can have its own process steps and workflows, and MRP (Material Requirements Planning) prioritizes component reuse and calculates the cost impact. Traceability and actual results are captured automatically in the system, which reduces manual reporting.

3. Real-time data for better decisions

The IFS Cloud MES (Manufacturing Execution System) can be connected to production machines, collecting data on downtime, production speeds and quality issues. Production staff receive real-time alerts, and management can see bottlenecks in a single view. This reduces waste work and improves asset utilization.

4. Industrial AI boosts circular economy results

IFS.ai combines cost, condition and emissions data, prioritizes work and part choices, and shows the impact of actions before decisions are made. Forecasts keep plans realistic and guide remanufacturing choices whenever they are the better option compared to producing a new item. What-if scenarios help turn these choices into work orders and part selections on the shop floor.

Summary

Sustainable growth happens when products stay in circulation longer and materials remain in use. Remanufacturing reduces emissions and saves natural resources while also delivering financial benefits for companies. IFS Cloud provides the tools companies need to manage their business based on data and turn sustainability into a competitive advantage.

This blog post is based on IFS publications. Read more: IFS blog.